From safety point of view it is essential to carry out strength and stability calculations of ships during loading operations. To make these calculations by hand without using a Computer is difficult, time consuming and open for mistakes. Since February 1998 International Maritime Organization (IMO) obliged ship owners to accommodate a computer and relevant software application able to carry out strength calculations for bulk carriers having length above 150 m. Afterwards this regulation was expanded on 1st of July 1998 under the scope of the rule coded as IACS UR S1 for all ships having length above 65 m. With the rapid proliferation of personal computers and obligation to make longitudinal strength calculations by computers, ship masters have been willing to use software applications also for stability calculations.

Delta Marine together with its solution partner Mesh (Mesh Engineering & Software Co.) provides a ship loading software which would meet precisely the requirements of the customers. Named as DeltaLoad, this software application is customized based on particulars of the ship such as type, dimensions, compartmentalization, etc. Basically DeltaLoad is a tool to carry out draft, trim, list, longitudinal strength, intact and damaged stability calculations interactively with the user as result of virtual loading operations of standard loads (ballast, fresh water, fuel oil, lubrication oil, etc.) and nonstandard loads (cargo). In the meantime documents and information such as draft survey report, loading report, hogging/sagging calculations, loading/unloading optimization can be produced using the software. DeltaLoad is also capable to present integration interface to many different tank level measurement systems to get tank filling level information constantly online.

DeltaLoad is a software product which can respond the request for digital intact and damaged stability calculation in ships either operated or chartered by to major oil companies, meet the requirement to run online and integrated with the tank level measurement system in parallel with the technological improvements in automation applications and -especially for container ships- fulfill the need to use a software application for loading and automation operations in order to maximize the amount of cargo and maintain close cooperation with container terminals.

Autoload is the most advanced universal loading computer software designed to estimate and control parameters of stability, strength and floating status of virtually any type of ships - bulk, break bulk, tanker, ro-ro, container, heavy lift, naval, cruise, fishing, survey, supply vessel. Autoship Systems Corporation is a marine software developer of innovative onboard stability, load planning and an integrated CAD/CAM design program suite. Safety and regulatory compliance demand accurate calculations for metrics like vessel longitudinal strength and stability. Rely on LR SEASAFE to deliver this across design, operations and cargo planning for all types of vessels and offshore structures – from passenger ships, oil tankers and gas carriers to semi-submersibles and jack-up rigs.

Edison-Chouest.gif' alt='Ship Stability Calculation Software' title='Ship Stability Calculation Software' /The Guide provides advice for Masters, Marine Superintendents and others, such as STS service providers and transfer organisers, involved in the planning. FluidRay RT The most advanced realtime renderer on the market now has Rhino.

Data Entry

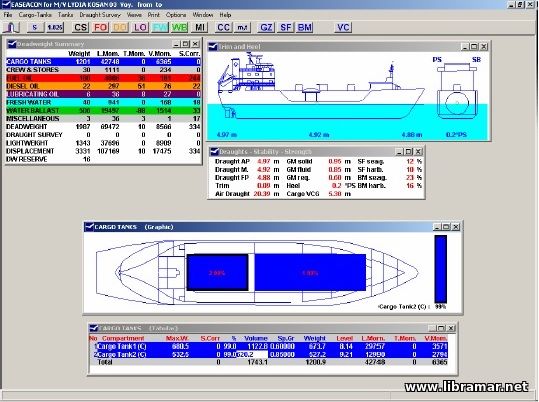

The loading data can be entered manually from the compartment list or from the selected compartment in the graphical interface. In case that an electronic tank measurement system exists on the ship, it is possible to establish a communication link between this system and DeltaLoad via an online communication add-on module that ensures the interaction of two systems through the exchange of data either at desired times or continuously.

Intact Stability

When a loading data is changed in a compartment DeltaLoad is able to calculate automatically the new equilibrium status (as draught, trim and list) of the ship. The compliance of the criteria, which is calculated from the static stability curve, is checked with IMO criteria.

Damage Stability

The compartments that can be damaged according to the damage standards determined in Marpol or IBC Codes are automatically damaged at given loading condition and the criteria are checked for every damage case. This feature provides damage scenarios without any requirement of expertise about damage stability on user side.

Longitudinal Strength

When a loading data is changed in a compartment, the new equilibrium status (as draught, trim and list) is automatically calculated and weight and buoyancy distribution is generated according to the new condition. The load distribution is calculated from the difference of weight and buoyancy distribution. Calculating the integral of the load distribution gives the shear force while calculating the integral of the shear force gives the bending moment. The calculated shear force and bending moment values are compared with the allowable values given by the classification society for the control points.

Container Loading

A special loading editor and reporting tool is provided for container loading. The loading cases can be provided in standard “EDI” format in order to be used in the ship and/or by loading ports.

References

SPS Overview

The name SPS stands for Ship Planning System. SPS is the ultimate graphical stowage planning software that provides powerful tools for planning various types of ships and cargo.

Its operation is based on true 3-dimensional model of ship and internal compartments. That delivers accurate calculation results and enables 3-dimensional visualization of the ship and cargo during the planning process.

Due to its modular structure SPS can be configured for virtually any type of ship. Putting together combination of modules makes SPS perfect stowage planning tool for multipurpose ships.

SPS is most suitable for installation on board the ships as a part of loading computer software and in shore based operations where the ship’s particulars and documentation is available well in advance before commencing the cargo planning process.

Through the years in operations SPS has gained reputation and popularity among the ship planners and deck officers in the most prominent shipping and stevedoring companies all round the globe. With continuous development of advanced functionality it maintains its position as the leader among the ship planning and loading computer software on the market.

Highlights of SPS

Graphical User Interface

The most remarkable characteristic of SPS is its graphical capability. Extensive use of computer graphics presenting cargo items of various shapes in their exact stowage positions on the ship in schematic and 3-dimensional isometric views, simple and intuitive ways of stowing and moving cargo around with drag-and-drop function is the hallmark of our ship planning software.

Ship Stability Formulas

Modular Structure

Different types of ships require different methods of cargo planning and style of stowage plan presentation.

Modular structure of SPS allows tailoring it to wide array of ship types and cargoes: RoRo; container; heavy lift and project cargo; bulk (dry and liquid); break-bulk; open hatch; tween deck, and any combination of the above ship types.

The programming modules exchange data in real time, making the process of planning multipurpose ships smooth and hassle-free within one software application.

To learn more about SPS please examine some of the solutions clicking on the respective links at the side bar menu.

SPS can be connected to Autoload, the most advanced stability analysis software, which provides real-time accurate feedback on ship’s hydrostatic parameters and floating status in the process of load planning. Combination of SPS and Autoload makes it perfect loading computer system for use on board of any type of ships.

Click the link to read more about Autoload stability module …

Scalable

The modules of SPS can be deployed as stand-alone applications on individual computers. At the same time the entire software system can be installed on the networked computers throughout your offices and integrated with your in-house information system bringing ship planning and cargo data processing on one software platform.

Voyage scenario

The functioning of SPS is built on the concept of total voyage scenario. That means the user can plan not just one port condition at a time, but optimize utilization of cargo space and ship’s capacity through the entire voyage. As additional benefits to that SPS provides:

- ability to instantly switch from one port condition to another to make fine-tuning of the plan;

- automatic update of the stowage plan when switching from port to port;

- automated control over possible stowage conflicts in the future or previous ports safeguarding the user from unexpected nasty surprises;

- possibility to plan and control cargo re-stows and shifting.

Drag-and-drop stowage method

The main method of stowage planning in SPS is dragging the cargo in graphical plan with the mouse and dropping it in the desired position. In the process the program renders the cargo 3D geometry based on its dimensions.

Built-in Stowage rules

There is a set of automated stowage rules in SPS that the planner can select and employ when stowing mass cargo or multiple units of breakbulk cargo. The program performs automatic check of stowage limitations and possible stowage conflicts and alarms the user if any problem is detected.

Cargo List

Important part of SPS is the searchable Cargo or Booking List with its very well developed functionality. Here the user can analyze and monitor type and amount of cargo stowed, yet to be stowed, its properties and characteristics. Ability to sort and filter cargo by various custom criteria facilitates the work with the Cargo List and makes cargo data analysis and tracking easy.

Electronic Data Interchange

SPS can be fully integrated in the ship operator's logistics chain of cargo data processing through the well developed EDI interface. SPS supports several standard UN / EDIFACT protocols, custom EDI protocols can be added as well.

Reporting capability

Basic Ship Stability

All stowage planning culminates in the set of reports. SPS provides very well developed reporting engine that allows the user to produce stowage plans and various cargo statistics reports in electronic PDF format. These reports can be printed, archived or sent as email attachments.

SPS provides management solution that improves cargo handling efficiency, utilization of ship’s capacity, and fully integrates planning operations into the real-time logistical chain.

Ship Stability Pdf

Contact us to find out which solution may best suite your operations or how we can tailor it to your specific needs.